Worker Stories

WORKER STORIES

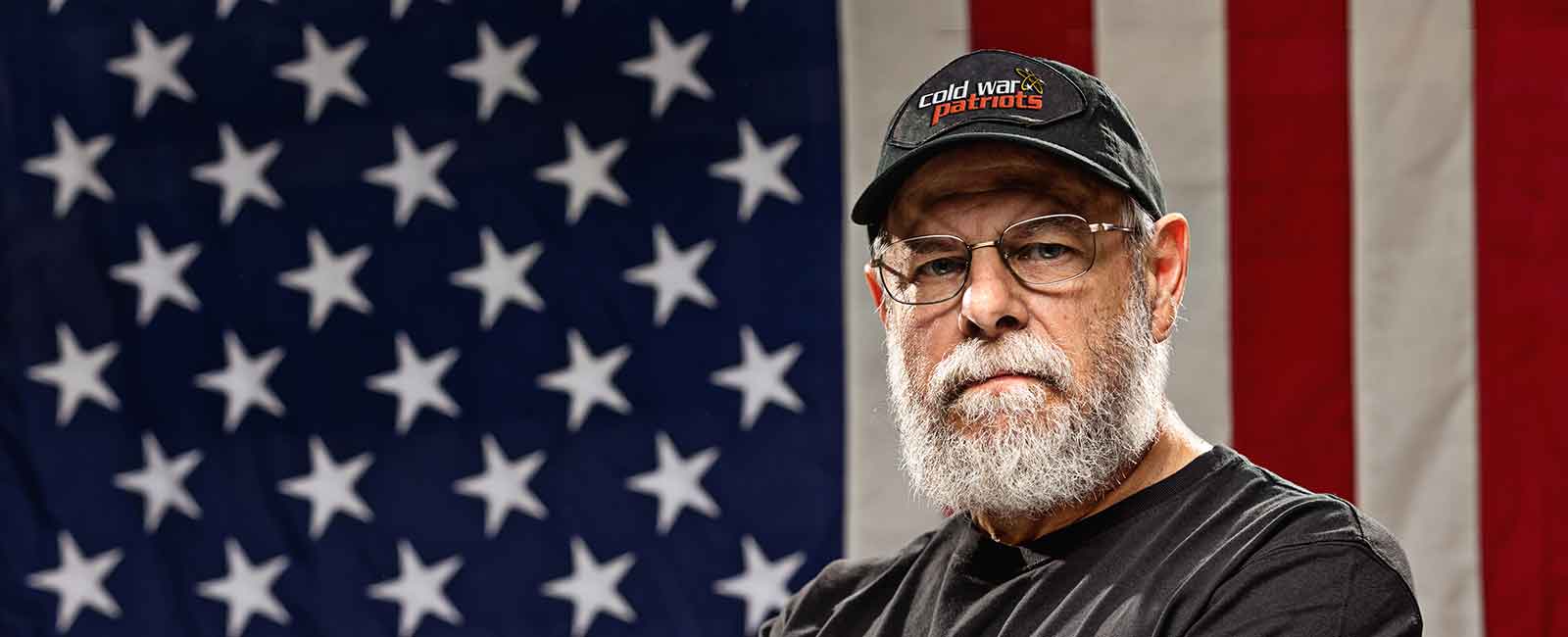

Many of the stories we’ve collected from Cold War Patriots began as a living history project to celebrate the first National Day of Remembrance on October 30, 2009. These personal accounts bring out the richness of history, and we encourage people to share their stories.

If you are interested in sharing your story, we have two steps to submit the details to us:

-

- Download the PDF for the Worker Profile in Strength and mail it to us at: Cold War Patriots

P.O. Box 18916

Denver, CO 80218 - Or, email us your story and pictures, if you have them.

- Download the PDF for the Worker Profile in Strength and mail it to us at: Cold War Patriots

We include some stories in our CWP newsletter, our website, and in other areas to help educate people about this unique time in history.

Please note that by sharing a story and/or a photograph, you release your likeness and story for CWP to use, and grant CWP permission to use it in the ways that we’ve noted above.

Read other worker stories:

Years worked: 13

Facility and job title: Ambrosia Lake, Uranium Miner

Tell us your story:

I started working in the mines when I was 20 years old. I just got back from a tour in Vietnam. I started in July of ’71 in a mine called the dog mine. The company was Four Corners Exploration. I drove a young buggy underground. This mine was an incline mine.They lowered you down in a muck car. From there I worked at 30 West for Kerr-McGee. I ran a mucking machine there, cleaning under the raises and chutes. I worked at the Johnny mine for ranchers. Maxie Anderson the balloonist owned it. I was a superintendent there. I went back to Kerr-McGee for a second time. I also worked sinking shafts for Harrison Western & Cementation. I worked as a pipe fitter for ICS in the Gulf Mineral Resources Mine for different companies. While working in the mines I got hit by a train underground, caved in a couple of times. I have heard of a lot of friends dying of a lot of things, Lord help us all.

Years worked: 38 years, 3 months & 6 days

Facility and job title: Goodyear Atomic Martin Marietta/ Process Operator

Tell us your story:

On 3/8/54 I hired on as a Production Process Operator. I attended operation school there until August 1954. In about the middle of August, 1954, we started leak testing for leaks and flaws on equipment that construction had begun to install. As construction progressed and time rapidly passed by, it was time to see if the new atomic plant worked. It certainly did; and I had the honor of valving in the first introduction of uranium gas to the new facility. My duties were doing various jobs in separation of 235 uranium atoms from uranium 238 atoms that were used in reactors and other uses. There was a great danger of being exposed to radiation from uranium and other highly toxic chemicals which were used in the atomic plant. Many times I experienced a high body count of radiation. One time I remember a valve broke on a 10 ton cylinder that I was filling with liquid uranium 238. I quickly valved off the line, but not before it filled the withdrawal room with uranium vapor. I was completely covered like someone had thrown flour on me. They quickly rushed me to the dispensary and soaked me in ice. My skin was slightly burned and I had a case of heavy metal poisoning in my system. I had numerous other experiences in my work there. But all things considered, I had a great job and have many memories.

Sincerely, Ralph E. Schisler

Years worked: 26 years 11 months

Facility and job title: Shift Foreman in Stores Department

Tell us your story:

I started working at Goodyear August of 1953, retired July 1, 1980. I started in the Receiving Department and later transferred to the Stores Department. I worked 23 years as an hourly employee and the last four years (approximately) as a shift foreman. I was in the group picture of the employees hired in the first year of the start of the Goodyear plant. This means that I saw the building of all the permanent buildings at the plant site, as well as all the streets. I really enjoyed the time spent at this plant and the company in charge of the plant. Now at the age of 95, I am still going strong and enjoying retirement.

Years worked: 37+

Facility and job title: Piketon, Ohio – Maintenance Mechanic 1st class

Tell us your story:

My hire date was November 16, 1953 at age 23. I retired 37 years later, July 1989. I worked as an hourly employee in the Maintenance Department. My entire career was with Goodyear Atomic and Martin Marielta Corporation.

The early days were exciting times. The hourly people knew nothing about product or equipment and supervision knew even less. It was a learn as you go process for everyone.

We were all exposed to hazardous conditions without realizing it. I have seen compressors opened to the atmosphere in the X720 building and filled the entire building with P.G. We just didn’t know any better, but someone should have.

I also spent years working in the valve shop where we were exposed to asbestos. Water and steam valves came into the shop covered with asbestos, which had to be cleaned off with wire brushes and scrapers. I have recently been diagnosed with Asbestosis. This should not have happened.

I spent the latter years of my career working Scale Maintenance out of X720 building, in all process buildings, all material handling and material storage buildings on plant site. We were able to develop the best and most respected weighing system in the nuclear energy business, both for purchasing and buyers of our product. H.G. Montavon (deceased) and I were mainly responsible for developing and maintaining this weighing process. We were very proud to admit to that.

Walter K. Roe

Years worked: 1945-1976

Facility and job title: Pile operator at Hanford, WA

Tell us your story:

Dad worked 31 years of three different shifts a month at most of the areas. During that time he received three awards for suggestions on improving the processes used.

We lived in a B house until 1957, before moving to the Kennewick highlands. Dad went by bus to the atomic site making a work day of nearly 12 hours.

Dad died in May of 1978 of cancer, and his wife, Eleanore, was given financial compensation for his death at 67 years of age.

Although Dad was born in Canada, he was a true American patriot.

Years worked: 35.5

Facility and job title: 1949 – K-25, Painter 5 months

Tell us your story: 1953 – 1988 Y-12, 6 years Millwright, 7 years Red Mccombs, Approx 17 years as a maintenance supervisor.

Years worked: 1959 – 1982

Facility and job title: Kerr-McGee Company – Miner

Tell us your story:

In 1958 I came to Grants looking for a job, and warmer weather for my family and me. I had worked seven years in Lark, Utah and four years in Gilman, Colorado as a miner. I was hired at the Kerr-McGee mill and worked there for one year. I then started working in section 30 west of Kerr-McGee Mine. I worked in sections 22, 24, and 30 West.

I worked as shift boss the last five years. I had some good workers working under me. It was a lot of work and sacrifices but I enjoyed my work. I don’t have any bad memories of being a miner.

Years worked: 3.5 years

Facility and job title: Mines Development Inc, Edgemont, SD – Operator

Tell us your story:

I was 26 when I went to work for MDI. I worked earlier for the local grocery store after doing three and a half years in the U.S. Army. With a growing family I needed a job that paid more, and a lot of my friends worked at the mill.

I was an operator and worked in the Rod Mill, Mud Mill, RIP circuit and with yellowcake, and the lab. There wasn’t much you didn’t do at one time or another. The conditions at the mill were extremely dusty, making it hard to breathe or see across the room. We had no safety gear or protective clothing. You wore your clothes home to be washed with your family’s and they would have at least three days of pollution on them. We never wore a badge, and the only monitors were put in different areas. If they were too “hot” they would throw them away and put new ones out after some clean up. Some guys carried uranium in their pockets as they heard it would make them sterile. The mill was buried in a Superfund Site along with millions of tons of top soil from the yards in Edgemont, South Dakota, covered and will be monitored forever as we know it.

Many of the workers and I had bad coughs due to the dust and would cough up black phlegm. This went on for a year after I left the plant.

I worked alternating shifts and would come home on swing and midnight shifts and go to bed without showering so I wouldn’t wake the family, or I was just too tired. I shudder to think now how my wife breathed the dust from my hair and body.

My wife dried fresh flowers with boxes of “Silica” from the mill pile and stored them under the beds of the girls and ours.

I brought home chunks of processed vanadium for the girls to take to school for Show and Tell. They would run water over them to hear them crackle and had them in their bedrooms until a biology teach took them for his collection. I was told at the mill they were harmless.

I was diagnosed with stage 3 kidney cancer three years ago, and last year was finally accepted for chronic kidney failure last March. This August, 2009, I was diagnosed with prostate cancer. If the Charlie Wolfe Act doesn’t get passed, I won’t be covered for this new cancer.

The day I got your letter to write my story, we also got the bad news that our two youngest daughters have invasive breast cancer, and will lose their breasts and need treatment. One daughter has insurance, the other doesn’t. My oldest daughter has had thyroid, neck, and throat cancer and suffers from lymphedema in both legs.

All of my family has suffered from tumors, behind the knee at 11, uterine cancer, thyroid tumors, neck, gall bladder tumors and gangrene of the gall bladder. They all suffer from muscle, tendon and leg pain.

My family and I have surely paid our dues for “Freedom”.

Charles “Gene” Hudson

Years worked:1956 – 1993

Facility and job title: Albuquerque, NTS, LASL, Oak Ridge Facilities (Y-12, K-25, X-10)

Tell us your story: Held positions of Design, Product, Project, Systems Engineering, Operations, Group Leader for Rover Program (Nuclear Rocket), Nevada Test Site. Jackass Flats, Nevada.

AEC and DOE Government Contractors were ACF Industries, South Albuquerque Works (Nuclear Division), Union Carbide Nuclear Division, and Martin Marietta Energy Systems, Oak Ridge.

Years worked: 1974-1985

Facility and job title: Oak Ridge National Laboratory – Security Inspector

Tell us your story:

On March 2, 2008, I lost my beloved husband. Billy Ray was an employee at ORNL in security. He took his job very seriously for he had always served in other areas of protection before employment at the Oak Ridge Plant (civil defense director, city policeman, rescue squad officer, etc.) This was his life – protecting those things he held dearly!

On this special day, May 22, 1978, President Jimmy Carter visited the ORNL. Billy Ray is seen in these pictures as not only safe-guarding our President, but securing the Plant.

I am sure if he was here to tell it, he would say that this was one of the most eventful days of his life!

I felt as having an opportunity to share in the Cold War Patriots “National Day of Remembrance” that this story had such significant value in remembering those who are willing to give their life in order to protect our freedoms!

Thank you – Mrs. Billy R. Lawson

Years worked: 3, April 1, 1954 – April 30, 1957

Facility and job title: Y-12 building 9212, Chemical Operator

Tell us your story:

I was 20 years old when I started my job at the Y-12 Facility. I started in the foundry where I handled tons of U-238 and was later transferred to the reclamation area of 9212 where I was involved in reclaiming U-235. This was a long process in which we took any material that was contaminated with U-235 and removed the U-235 for reclamation. I was exposed to many toxic materials including acids, caustics, ammonia and of course, U-235. I have developed several skin cancers which have been surgically removed, and a lung problem called Plural Thickening, a condition probably from inhaling and ingesting toxic materials, so say the doctors doing the examinations. It was due to an infection caused by toxic materials.

Thank you for making me a member of “Cold War Patriots” and keeping me updated about activities.

Daniel Terry

Years worked: 1943 until 1987

Facility and job title: Chemical Operator

Tell us your story:

I helped build 500 houses in Oak Ridge, the summer of 1943 with Stone and Webster Contractor. On November 25, 1943 I hired in at Oak Ridge National Lab. I worked in building 3019, involved in making plutonium, uranium and radio isotopes, waste handling, burial grounds, tank farm work, taking all kinds of samples, and chemical make up in the 3019 building. Also, two more very important buildings, 3026 C & D, and building 3517 handling fission products in the pilot plant. I was awarded the E-Pin award for helping make the atom bomb.

Years worked: Off and On 1950 – 1995 – Across the US, Different Jobs

Facility and job title: Office Power Plants – Certified Mechanic for Y-12

Tell us your story: It is so sad how proud the US was at one time. In four years, it has turned upside down. My Aunt was locked up in the valley. I was 5 years old at the time. My Aunt name was Maude Jett Farmer from Halls, TN. My Dad’s name is James Jett, he worked at DOE in ’45. Most of my kin get a job at Oak Ridge whey they started hiring in Oak Ridge. I will sum this up.

I know now what it means. God Bless the USA. I have so much, it’s not enough room. Keep the U.N.S. Safe!

Years worked: 1946-1989

Facility and job title: Painter for Rust Engineering working at Y-12 and K-25

Tell us your story:

My father J.C. McGhee, along with several of his brothers, worked at the Y-12 and K-25 plants in Oak Ridge doing various jobs subjecting them to asbestos, various carcinogens, and radiation. My father was a painter for Rust Engineering. He used to paint the inside of the chambers at &-12, among other jobs. I remember many days he would come home with asbestos on his overalls and we would wash them and hang them on the clothes line to dry. Like many other Oak Ridge workers, he never talked about the job he did, so I don’t know too many details. He passed away in 1993 from lung cancer attributed to the work he did, as well as smoking cigarettes.

His brother William Earl McGhee and son Roger Douglas McGhee both worked at the plants in asbestos. His brother Earl passed away from lung cancer in 1997 or 1998. Earl had asbestos of the lungs as well as his son Doug. Doug passed away August 23, 2010 from emphysema and asbestosis of his lungs.

I wish for all the McGhee family of Oliver Springs, TN to be remembered for their services to our country, both during the war and after.

Sincerely,

Alice F. McGhee

Years worked: 11

Facility and job title: Maintenance – Machinist

Tell us your story:

At this time in history our country was being challenged again. We were in the process of increasing efficiency by decreasing the tolerance or clearance between two rotating parts increasing friction and more gas, or a finished product. My job was matching the compressor and rotor to a .005 tolerance on the 29 and 33 ton rotors. The rotors were placed on live centers and machine tipped to the tolerance necessary on a monstrous lathe. As it turned, it is my assumption the toxic chemicals or gases were being released and blown over my body. The result was for or five years after retirement, I had cancer of my lower lip, which was removed, also cancer of the nose, the arm, and the big one – colon cancer.

I loved my job – also one I’ll never forget.

Sincerely,

Raymond Mingus

Years worked: 26

Facility and job title: Portsmouth Gaseous Diffusion/Centrifuge

Tell us your story:

In February of 1974, I was the first union (OCAW) female to be hired off the street at the Portsmouth Diffusion Plant.

For one year, I was employed as a custodian. The next ten years kept me working as a converter mechanic.

When GCEP offered bids I became the first female operator in the assembling and disassembling of the centrifuges.

Later, the U.S. government closed that facility and I returned to the Portsmouth Gaseous Diffusion Site where I completed my career in shipping/receiving with an accumulation of twenty six years of enjoyable service.

Being a “pioneer” of the Cold War Patriots is an honor for me!

Betty J. Koehler

Years worked: 1954-1983

Facility and job title: Portsmouth Gaseous Diffusion Plant

Tell us your story:

I began working for Goodyear Atomic Corporation as an Accounting Clerk in the Finance Division in 1954. I began in General Accounting and was transferred to Engineering Costs and Property Records after a few years. In 1966 I was transferred to the Industrial Relations Division Training Department as a Conference Leader. In this capacity, I developed training courses in everything from defensive driving to value engineering, and then taught them to foremen through superintendents. I covered all the orientation training of new employees. In 1974 I was made Administrative Staff to a Superintendent, and in this capacity I had the responsibility of equipping the dining hall and liaison with the Contractor Management. I further served the Superintendent in other pressing matters. In 1977 I was transferred to the General Manager’s Division, and instruction to establish an office of Equal Employment Opportunity, study the law, and train others in the operation. I continued in this endeavor, recruiting women and minorities to responsible positions, overseeing the hiring and advancement of both, until my retirement on April 1, 1983.

I was diagnosed with lung cancer in 1990, had a third of my right lung removed at Cleveland Clinic, and did not require radiation or chemotherapy. I do have chronic breathing problems, but I cope at 88 years of age.

Years worked: 1971-2002

Facility and job title: Rocky Flats Plant – Chemical Engineer

Tell us your story:

I mainly worked in Buildings 779, 771, and 371 in the chemical research and development groups. I also worked in the Special Recovery Group for processing hard to recover actinide material. My main area of focus was the recovery, separation, and purification of actinides by anion exchange and precipitation methods. During my career at Rocky Flats I either authored or co-authored eleven external report publications, six journal articles/ book chapters, eight presentations, three record of invention applications, and twenty internal reports. In 1983, as part of a team, I received Industrial Research and Development Magazine IR 100 award presented to Rockwell International for the recovery of americium using chromatography techniques. During the closing of Rocky Flats, I, along with others, developed the magnesium hydroxide precipitation process that recovered all the plutonium solutions remaining in Buildings 771 and 371. We developed the cerium nitrate process that was utilized to decontaminate all the glove boxes and tanks in Buildings 771 and 371. We also developed the Nochor absorbent process that solidified contaminated solutions. I was fortunate to work with many brilliant individuals who were also good friends.

Years worked: 1981-2004

Facility and job title: Buildings 771/371

Tell us your story:

I started my career working in the garage the first month, then signed a posting for building 771 as a chemical operator. During the ensuing years, I became a supervisor for production, then Production Manager, and then Shift Manager for buildings 371, 374, 771 and 774. During this time I became involved in the alleged “midnight burning” of the incinerator and was interviewed by the FBI. I was also a manager when the lawsuit was brought against the security guards for their “low ready” assault. When production shut down and was shipped offsite, I was involved in removing material from the stacker/retriever for treatment in building 707. My group was responsible for the shipment of material to 707 of over 300 items. Following that, I became a subject matter expert for material transfer, which included the installation of a measuring and verification line, and the safe shipment of the materials. After that I moved into Nuclear Material Shipping until the final shipments to offsite storage. I was employed even after the sewage station was removed, and the “eye in the sky” water tower was removed. I retired in 2004 after 23 years of continuous service, several PIs, and many commendations. I was proud of the work I did in defense of the country.

Years worked: 32 years from 1940 – 1976

Facility and job title: Union Carbide Mill – Mill site/Shift Foreman

Tell us your story:

I was born in Red Mesa, Colorado 1917. In the mid 1930’s my family moved to the region of Uravan, Colorado. My father went to work for the United States Vanadium Corporation. In those days, Uravan wasn’t much, just a small mining town off Highway 141 near the San Miguel and Dolores Rivers. Small town Western Colorado was a wonderful place to raise children and build a family. Times were difficult and jobs were few. After high school, I put my application in for work at the mill in hopes to work with my father. During those times employees were chosen at random off the street. Many men would gather daily outside the gate of the mill in hopes that they would be chosen to go to work. One such day, my dad told me he had spoken to the supervisor about my coming to work. The fix was in. When I showed up that next morning at the gate outside the mill with my brother Alva, the supervisor came to the gate and asked was there a Hiett in the crowd. My brother said yes and was picked to go to work instead of me. I went ahead and found work on a local ranch for a couple of years. In 1939 the mining company purchased the Club Ranch just north of the mill, in order to obtain the water rights to the river which grew to become an important part of the mill’s operation. The ranch also provided cattle, vegetables and fruits for the town. I was finally hired by the company to work the ranch that summer. At the end of the summer, I was transferred to work at the mill for the next two years.

In 1940, I was called by the U.S. Army. After basic training I was first stationed at Camp Pickett in Virginia. Upon learning I had worked in the vanadium mill in Uravan, I was transferred into the core of engineers under General Grove at Oak Ridge, Tennessee where they were working on the Manhattan Project. One thing led to another, and because I had experience working in a vanadium mill I was once again transferred as a U.S. Army Technician to help oversee the mill operation at Uravan, Colorado. At this time the mill was being operated under the direction of the U.S. Government as part of the Manhattan Project. They were separating uranium and vanadium from the ore and shipping the raw materials to several locations within the United States.

Little was known about the impact of the uranium dust or its effects on the mill workers at this time. In 1945 after the war had ended, the mill was closed and the plant shut down. I moved my family to Oregon to obtain work in the lumber industry. We lived there until 16949 when I was contacted by Union Carbide Inc., advising me that they were going to reopen the mill and asked if I was interested in a position. I, of course, was very interested and we returned to Uravan, Colorado.

The reconstruction of the mill began in 1949 and was completed in 1950 when the plant was reopened. For the next 26 years we continued to separate the vanadium and uranium from the ore and shipped it around the country. Among the many uses for uranium when processed properly the U234 we mined was turned into U238 used for Atom Bombs. Other research was being done in many technical areas and uranium is now used in a variety of high tech applications. For example, uranium is currently used for medical applications and has proven to save many lives in a number of specialty areas.

During the years as a civilian working at the plant, our family grew to include five children. I retired in May of 1976. It was in the 1960s after my retirement that a Dr. Sockamon in Grand Junction, Colorado began studying the effects of radiation dust on employees. As a result of his research and findings, Union Carbide Inc. established several new safety applications for plant and mine workers. The plant installed various size dust collectors throughout the mill and required wor

kers to wear respirators within specified locations of the mines and plant. Even with these precautions, many of our workers contracted cancer and pulmonary fibrosis. It seemed to me that the workers who smoked were most affected.

During all my time at the mill there was very little employee turnover. Although many of the mill employees have long passed away, we tried to stay in touch with each other as best we could.

One story I remember that really alarmed us at the time, was when one of the mill workers drove up the hill to the supply shack to get some tools and equipment needed for repairs. He had forgotten to apply the parking brake on the truck. The truck rolled down the hill and crashed into one of the large propane tanks. The whole camp was put on alert and employees were evacuated as fast as possible. The crash caused a four inch line to come loose from the tank and created a large cloud of propane. My supervisor was driving down the hill from another part of the plan and didn’t know what had happened. He drove his truck into the cloud of propane. We were amazed that the truck didn’t cause the propane to explode. Instead, the truck just stopped in the middle of the cloud and died. It must have been the lack of oxygen within the cloud that caused the truck to die. Whatever it was, it saved the camp from going up in flames. It all ended well.

Ten years after my retirement, I was diagnosed with pulmonary fibrosis which I am still suffering with today at the ripe old age of 92. May God bless all those I had the chance to live and work with over my career.

Cliff M. Hiett

Years worked: 8 Years

Facility and job title: Miner- Driller/Blast

Tell us your story: I have worked at Gateway, CO for 8 years as a driller. Had I known that this was a dangerous uranium to work with I would have thought twice, however, I believe with God leading, I made a wise choice and that is to defend the United States of America. I am very proud to be an American-Native-Navajo Indian of Sweetwater, AZ. At the age of 75, my health is not the best anymore due to uranium exposure, or well as my family whom have been exposed. I’m very thankful to PCM then DOL with caring with Home Health Care in my own home. I am also thankful to DOL to provide professional care.

Thank you,

Dean Paul, SR

Years worked: 1965-1979

Facility and job title: Uranium Miner and Energy Pipeline Labor

Tell us your story:

When I was working underground I was involved in a cave in, where I got hurt real bad. I was lucky to survive. In those days of early mining there was not much safety, and we were exposed to a lot of toxins. I have lost all of my co-workers whom were also miners, and also three brothers who all worked in the Grants area mines. They all died of lung cancer. As for myself, I am still alive but not doing well. I don’t regret working in the mines because we were working for our country in the Cold War era. I do regret not getting help with my compensation and medical card. I have been turned down, but thank God I am still alive. I have a lot of trouble finding medical and employment records, even though I have been a union member for forty four years. I hope things will improve for future generations and won’t have to suffer or work in dangerous places like I did.

Thank you!

Tacho Valdez

Years worked: 6 years

Facility and job title: Uranium mines – all phases

Tell us your story:

I began working in the uranium mines when I was still in high school. At that time I mucked the ore with a shovel and loaded it into a wheel barrow. It wasn’t too long until we started using horse-drawn ore carts and during that time I learned to drill and set the charges. After spending two years in the army I returned to mining. By then we were using loaders and shuttle buggies. In all the years in the mines I never saw a mine inspector. For a short time I had to drill dry without even the aid of a jack leg. All the dust from the drilling settled into my lungs. Frequently I worked alone and had the complete responsibility of the operation. In 1961 mining slowed down and I left mining for the winter and never returned.

I had some very close calls during my years in the mine. At one time I was working in a large room in the mine. There was a little notch in the side of the room where the air pipe came into the mine from the compressor. I was turning on the air when I heard a noise like the sprinkling of sand on a screen. I looked up and saw a widening crack in the ceiling. I jumped back into that little notch just as the entire ceiling fell at my feet. Another day I was picking down loose rock, preparing the ceiling so that I could begin drilling. I was sitting on the scrubber of the loader with my legs over the side when I saw a big crack opening. I grabbed my legs by my ankles and rolled back into the seat of the loader. Had I been a second longer I would have lost both of my legs.

In many ways I enjoyed mining, but I have no regrets that those days are over.

Name: Sibyl Henson

Tell us your story:

Francis Wade Henson, Eng. Y-12 – 42 years Top Security Clearance (Father-in-Law)

Stan Martin – Cousin – Guard

Earl Lineberger – Uncle – Guard Y-12 – Many Years

Francis Henson worked on at least one Gemini or Apollo Space Craft.

Son, Tim Hester, serves presently near Washington, DC for State Department Services, Former Air Force linguist.

I was employed by Bechtel National for ten years.

Name: Donna Denton Ryan

Tell us your story: My dad, Malcolm Denton, worked at K-25 and Y-12 during the 40’s and the 50’s. There were five busses that carried the worker to Oak Ridge from Cumberland County and surrounding areas. We had a little stray dog named Biscuit. Everyday Biscuit would sit on our front porch about 3 pm. After three buses had passed, she would walk down our long driveway and sit until the fourth came. My dad rode that bus.

Part II:

Men from Cumberland County joined others who worked for free on Sundays and the pay they would have received went toward paying to build “Sunday Punch.”

Years worked: 18

Facility and job title: Chemical Processor, Uranium, and Electrical Drafting

Tell us your story: She worked as a chemical processor for 3 years whole waiting for an electrical drafting position. She retired in 1985, and began working in 1969 working at Y-12 and ORNL. She battled lung and bone cancer from 2000 – 2012. She was born 7/3/25 and passed on 7/7/12. She was the 1st woman from Tennessee to be elected National President of AMVETS auxiliary from 1989 – 1990.